| Sign In | Join Free | My chinacomputerparts.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My chinacomputerparts.com |

|

Brand Name : SZ

Model Number : Polyester Nonwoven Geotextile

Certification : ISO/CE

Place of Origin : China

MOQ : 20GP

Price : $0.3-$2.0/SQM

Payment Terms : L/C,D/P,T/T,Western Union,MoneyGram

Supply Ability : 8Ton Per Day

Delivery Time : Withine 15 days

Packaging Details : Roll By Woven Bags

Product Name : Polyester Nonwoven Geotextile

Process : Long-fiber Nonwoven

Feature : Anti Static

Length : 50-100 m

Type : filament Nonwoven

Application : Road Reinforce

CBR Burst Strength : 200-4000 N

Elongation : 25-100%

Width : 1-6 m

Weight : 150-800 g/m2

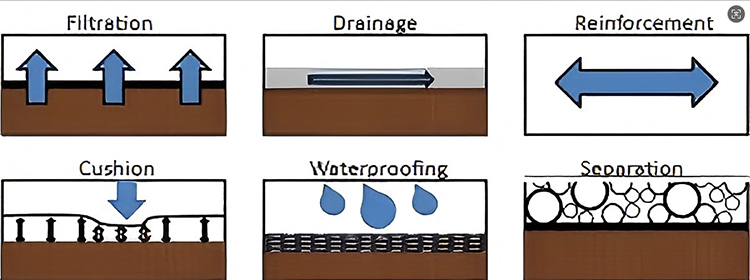

Polyester short fiber nonwoven geotextile generally has a width of 4-6 meters and a length of 50-100 meters. Polyester short fiber nonwoven geotextile has a certain degree of tear resistance and deformation adaptability due to its soft fibers, as well as good flat drainage ability, which can play a good role in filtering, isolation,reinforcement, protection, and other functions. Polyester short fiber non-woven geotextile is suitable for soil filtration, soil separation, soil reinforcement and other engineering projects.

1.Our company has a professional logistics team and reliable logistics companies with whom we have long-term cooperation. We can ensure that your goods are delivered on time.

| Maintenance Phase | Inspection Frequency | Key Maintenance Content |

| Construction period (from laying to covering) | Daily + comprehensive inspection before covering | Inspect for damage and splicing defects, and repair them promptly; avoid prolonged exposure to direct sunlight. |

| Initial operation period (within 1 year) | Once every 3 months | Check for loss or collapse of the overburden layer, and refill it promptly; investigate early damage. |

| Mid-operation period (1-5 years) | Once every 6 months | Monitor for signs of geotextile aging (brittleness, discoloration), and clean any blockages in the pores. |

| Late-stage operation (5+ years) | Once every 3 months | Focus on identifying and addressing areas of increased localized damage and detachment at joints, and strengthen protective measures. |

| Special environments (corrosive/open air) | Once every 1-2 months | Increase the frequency of inspections for corrosion and UV damage, and shorten maintenance cycles. |

2. Key Maintenance Points for Different Scenarios

Highway/Railway Subgrade: Monitor pavement cracks and subgrade settlement, and promptly reinforce with grout; backfill with soil to cover collapsed slopes, and perform heat fusion repairs on damaged areas.

Water Conservancy Projects: Regularly remove silt and floating debris to prevent pore blockage; conduct underwater inspections to repair tears or entanglements.

Landfill Sites: Ensure leachate collection pipes are unobstructed to prevent direct contact of chemical waste with geotextile; replace the entire product in the damaged area.

Landscape Greening: Backfill lost planting soil, clear drainage hole blockages, and prevent plant roots from puncturing the geotextile.

Chemical Corrosion Scenarios: Regularly sample and test corrosion resistance; immediately replace modified products if brittleness or dissolution occurs.

3. Maintenance Tools and Records

Essential Tools: Measuring tape, high-powered flashlight, camera, penetrant testing pen, repair adhesive/heat bonding machine.

Record Requirements: Establish maintenance files, recording inspection time, problem location, treatment measures, and follow-up results to ensure traceability.

Negotiation contact

Cathy

Yixing Shenzhou Earth Working Materials Co.,Ltd

( SHENZHOU GEOSYNTHETICS)

Add.: No.5 XinBei Road, Xinzhuang Industry Park, Yixing City, Jiangsu Province,China.

Post Code: 214221

M / WhatsApp/Wechat:+ 86 139 0153 8890

T:+ 0086-0510-8759 8866

|

|

290g Agriculture Woven Geotextile Needle Punched Type PET Staple Fiber for Slope Protection Nonwoven Geotextile Images |